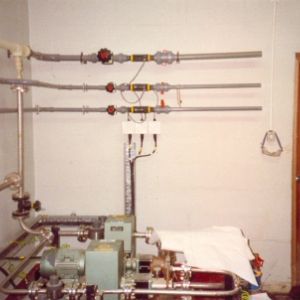

Pipework

PolyPlas Engineering have extensive experience in Plastic pipework installation across a variety of industries. We often work on projects that are solely pipework related but a large percentage of projects also have some sort of accompanying plastic pipework, connecting to tanks for filling or drainage purposes etc. We also manufacture manifolds, adapters, specials, auxiliary items such as pump enclosures etc to accompany any plastic pipework.

No matter which liquid solution you need to convey, we can work closely with you from design, to final installation to guarantee you receive a fit for purpose system that meets your exact needs. Depending on the solution the pipework will contain, we can offer various materials to suit the properties of the liquid. These include: polypropylene, polyethylene, PVC, PVDF, ABS and others.

Our fabricators have extensive experience in pipework installation including solvent welding, electro-fusion, socket fusion welding, butt welding and hot gas welding techniques. With extensive experience of working on site throughout the UK and over seas, we offer an out of hours or a shut-down period service if required, plus a genuine 24 hour phone answering service.